More stuff arrived! woohoo I swear its like christmas every two weeks lol

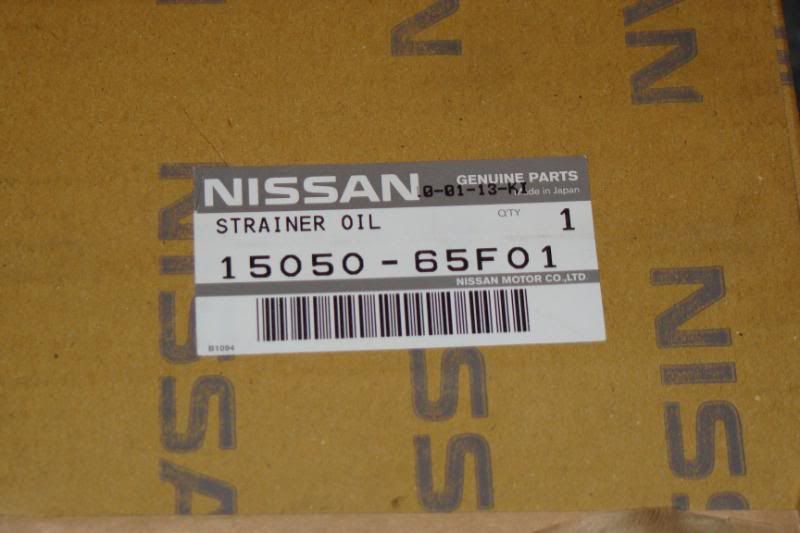

I decided to replace the s13 oil strainer with an s14 oil strainer.

First your going to have to take all 10x oil pan bolts with a 10mm 3/8 rachet. And remove the pan using a combo of a putty knife and hammer.

Next remove the 6x plate bolts with a 12mm socket with a 3/8 extension. Take note of location of the baffle plate before removing it

Once I took off the baffle plate I discovered lots of oil sludge gooo!

Heres me with some disposal gloves scraping all the old oil/sludge with my hands. I could be on the tv show "Dirty Jobs" for doing this.

Your going to need a 12mm socket and 3/8 extension for 2 of the bolts thats holding the oil strainer also a 10mm wrench

Once you remove the oil strainer notice the difference between the s13 vs s14 oil strainer the s13 has a smaller opening where as the s14 has a much larger one. The 10mm bolt for the s14 oil strainer is bolted to a different location and is a PITA to thread on two people helping you will make it easier to do.

First your going to put a new oil strainer gasket then "Loosely bolt up the 2x 12mm bolts"

Me and my buddy confirmed that using just your hands, magnet, wrench, needle nose pliers have all failed in trying to get this god forsaken bolt threaded on.

What we did find out to work just fine was positioning the bolt dead center having a small flat head screw driver keep it in place and "slowly" wrenching on it with a 10mm wrench.

Heres a better pic on how tight of space you have to work with thats why it's better to have the 2x 12mm bolts loosely tightened to allow for more clearance.

Once you have wrenched the bolt in far enough, you can finally squeeze the rachet wrench on it to make it easier to tighten.

Don't forget to tighten and torque the strainer bolts to 12-14ft lbs. Oh and as for the strainer bracket I just goodin tightened it. Once the strainer installed. Now reinstall the baffle plate and torque them to 4.7 to 5.5ft lbs. Then Scrape and remove all the old gasket from the oil pan.

Now apply gasket sealer with one continuous bead all around your new greddy oil pan!

Heres the hardware that came with the greddy oil pan the 4x larger bolts go to the sides of the oil pan where the 6x smaller bolts go to the front and rear. have an allen wrench on standy as well as these bolts. Position the oil pan and screw on all the screws "snug tight" wait about 10-15 minutes then proceed to torque to 4.7-5.5ft lbs. With that low of a number I just hand tightened them.

When I removed the Crank Pulley I uncovered more dirt/grime so I cleaned it up

Then sprayed it with 2x coats of high heat engine enamel.

This concludes my day.