Alrighty, time for update round 2!

So we left off with the SR deciding it hated life after one lap at the track. Well I got the car towed home and into the garage it went to be neglected until the fall.

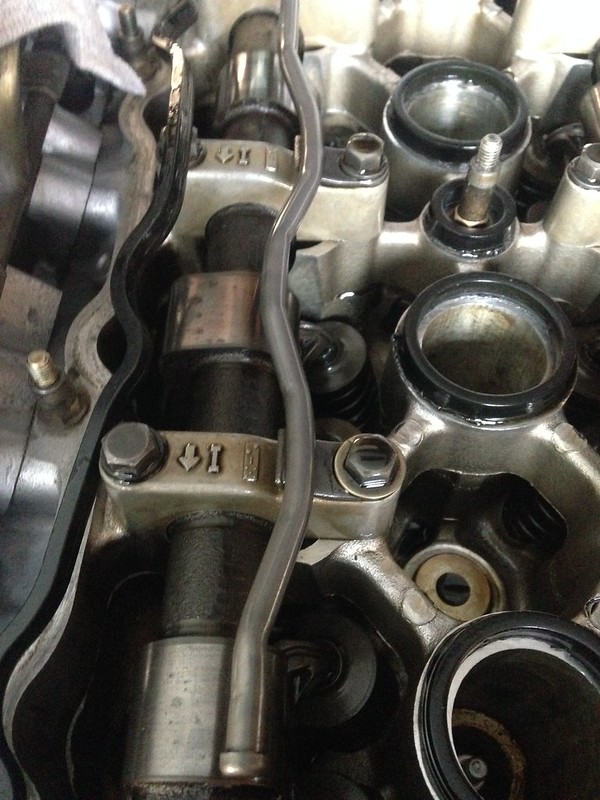

I started taking the motor apart in September. A few buddies of mine had suggested it might be a broken rocker arm, being such a loud clacking. With not much hope I pulled the valve cover off and everything seemed to be ok. Now I headed to the oil pan. I removed the oil pan and found shavings as expected, but no indication as to why it failed. Nothing seemed lose or falling apart.

Digging deeper I pulled off the oil pickup and found a huge hole in the mesh….. how did that happen?

I peered up in the oil pickup gallery and I couldn’t believe my eyes. I could see a washer sitting right inside the oil gallery loose.

There is my suspect that caused the malfunction, restricting oil through the pickup. I know I hadn’t dropped a washer in the motor bc I had yet to work on anything internal. All I had done was stripped and added the accessories and cleaned up the block.

Upon further analysis and direction from some knowledgeable SR friends. I was told the washer was a 10mm factory washer and they are old used in two places on an SR. On the bolts holding the oil pickup and its baffle and the caps holding the cams down. Well I had already taken the pickup off and all the hare wear was there so that left one other spot. I removed the valve cover again and instantly I saw the problem. All the cam cap washers appeared the same except one. One washer was a bright gold color. Clearly this one had been changed.

My suspicions are whoever owned this motor prior had done some or on the head/cams and dropped the front washer down the timing cover and just replaced it with another one, not to be bothered to search for the missing washer. It is still unclear to me how the washer broke through the pickup mesh but I also suspect that was done before I owned the motor, since I had only been driving it for 2 months on weekends or sunny days.

This gets even better for this motor as I found the oil filter relocation that the previous owner had installed was on backwards… Therefore the oil feed out was the block was going into the “exit” side of the filter and out the “feed” side of the filter block.

The motor was doomed since the beginning with the washer and oil filter relocation. Not to mention the flywheel and trans that the owner messed up on as well. I guess this explains why I would get poor oil pressure on idle on my gauge. I always assumed it was a faulty gauge as I bought used old Greddy gauges from japan with used sensors. The gauge would read normal on startup then fall low and would peek up and down with the Revs. The stock light didn’t come on either so I thought it was a faulty gauge.

I decided it would be more costly to rebuild this motor when I had a line on a built long block (with very low mileage, max 2 summers) for sale locally. This motor was built by a friend’s good buddy and I had personally seen the car running and driving. It’s always sketchy to buy an already built motor but a lot of my s-chassis friends vouched for the motor as they had ridden in the car so I felt comfortable. It was a cheap price so I couldn’t pass it up.

The spec list for the new motor includes:

- Stock head fully rebuilt, cleaned, polished and decked with factory cams.

- ARP head studs

- All ARP hardware throughout the motor; main and rod studs and bolts

- ACL race bearings all around

- Tomei connecting rods

- CP 87mm 9:1 pistons

- Greddy oil pan

- Cometic 1.3mm head gasket

Everything was of course honed, cleaned and polished and balanced the rotating assembly.

I picked up the motor one Friday night and saw that it had been sitting for a while in his garage and had collected a good amount of dirt. He had mentioned to me that the timing cover had been sweating causing the front of the motor to be caked with oil.

I couldn’t put the motor in the car being this way so I gave it a blast with the power washer and a bunch of degreaser. It came out decent but still wasn’t happy as my other motor was spotless.

[

I decided to paint the block and all the accessories like I did to the last one.

Much better! Now it just needs my Candy blue powder coated valve cover.

During the downtime of not driving the car I had debated selling my turbo setup. I really liked the 2871r and the power it made. But as most builds go I figured, “I’m here now, I have a built motor might as well have a cool turbo setup.” Lol

Staying true to my Japanese style I’ve always wanted a TD06. Although this is old tech when it comes to modern turbos, I wanted to keep that Japanese 2000’s drift aura and run one. Hardly anyone in North America runs one let alone Canada. It’s something cool to me when you open the hood and see a TD06 rather than “sick precision or Borge Warner turbo bro!” All the old school JDM turbos like Greddy, HKS etc have something awesome about them and sound so cool.

In addition, I’ve always wondered how the Japanese guys had such nasty sounding Sr’s. They sound so raw and absolutely scream! I found the key, TD06 and midmount! True iconic Japanese SR sound.

Being that Greddy hadn’t produced a mid-mount manifold in over a decade I was having trouble finding a decent condition one. I had stumbled upon a Australian shop that made an almost exact replica of the original so I decided to go for it.

Original:

New replica:

The only problem was that the dump pipe goes right through where the steering column is on a LHD chassis. Time for me to think of a clever way around that…

In the meantime I kept my eye out for a TD06 turbo in good condition. I ended up finding a complete kit on Yahoo japan randomly one morning before work. The buy now was super cheap so I quickly messaged Jesse Streeter to jump on it. A week later and I had a giant package at my door!

I scored a low km (3000 km) TD06-L2, Greddy 50mm type r wastegate, greddy turbo elbow and a Greddy Top mount manifold. I really wanted the L2 version as it is made specifically for a 2L motor and supposed to be great on an SR. I also have the 8 cm rear housing version of it.

Unfortunately, the manifold was cracked due to the massive type r waste gate. But that was fine as I wasn’t using that manifold anyway. Looks pretty cool tested out on the new motor.

In the meantime I sold my old turbo setup to cover the cost of the new purchase. I was now waiting for my new manifold to be made in Australia. In the next update I’ll show you my clever way of fitting the massive type R waste gate and hopefully bring the thread up to date to where I am now.

Thanks again,

Joe.