***** I ordered some braided nylon expandable wire sleeving and adhesive heat shrink to finish my fuse box relocation. I'm hoping it'll be here this week so I have something to work on. Anyway, on to the updates.******

So, I finally completed my catch can setup. For those that haven't been paying attention, I'm using an exhaust venturi to create vacuum in the system. Once I had the check valve mocked up along with the fittings, I could cut and assemble the line. I used some thermal sheathing to help prevent the line from being destroyed from the heat.

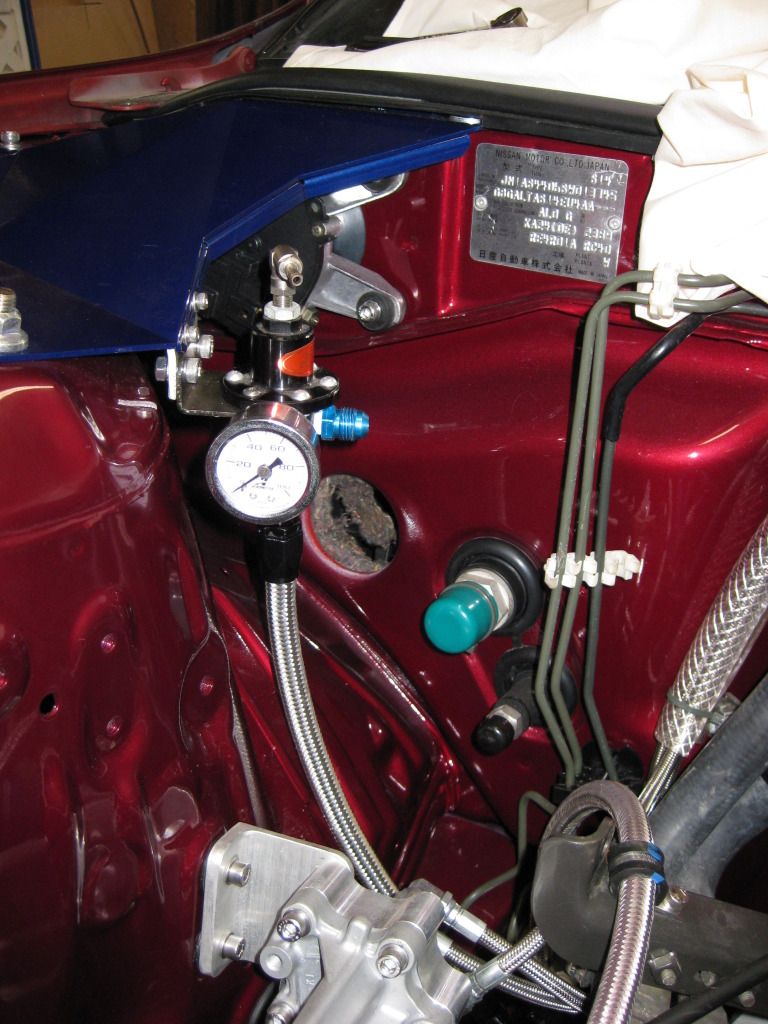

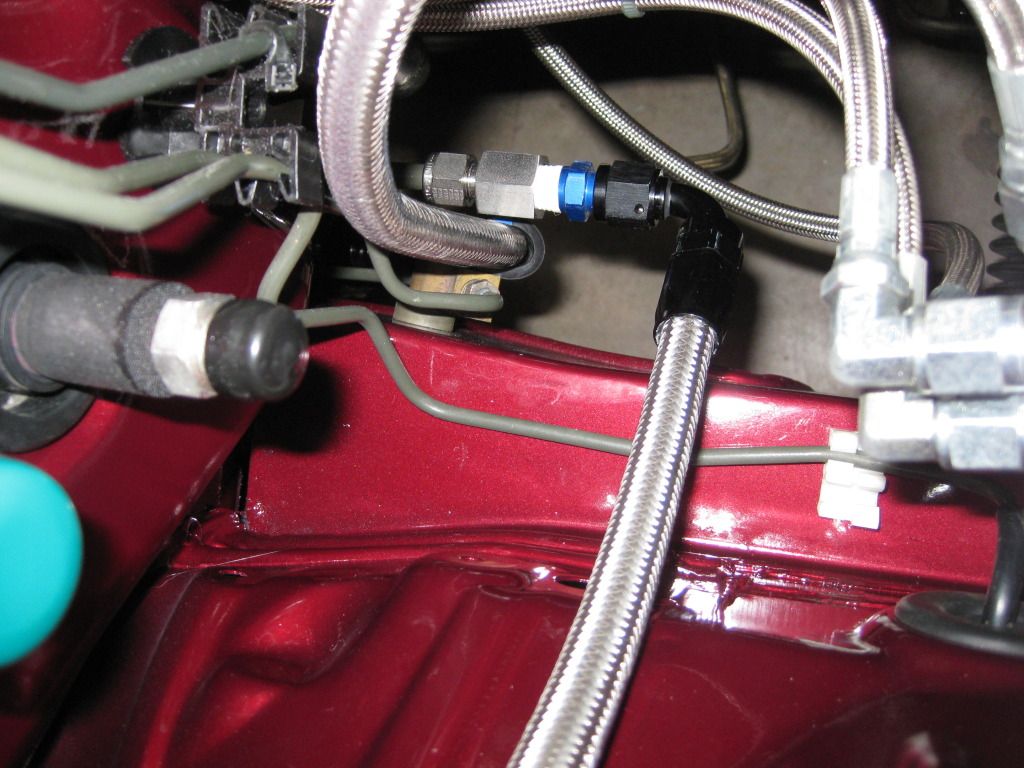

I had been fighting with myself for sometime on where to locate my FPR. I wanted to mount it in an easily accessible location for obvious reasons, but I couldn't invision how the lines would terminate to it where I wanted it. So while I was just tossing around ideas I found my final mounting location. I utilized the inside lip of my shakitto plate and with some scrap aluminum I had laying around, I created a bracket and had it mounted in a night. I have my fuel filter running up the inside of the passenger frame rail where I can get to it if I need to clean it. I'm missing one fitting from the rail to the regulator and I'll have the fuel system completed.

This evening I started making my cold charge pipe(from IC to TB). I'm using 2.75" SS piping that is unpolished. Once I have the pipe completely welded up, I'll polish it, but for the time being it is what it is. I'll need to do something like pie cutting to get a tighter radius on the piece that 90's down from the TB. I really am against pie cutting, but am very limited to what I can do with it. I've been trying to find a 2.75" x 3.5" reducing 90 hose coupler, but I've come up short in my searches. In the second picture you'll get an idea of how tight the turn needs to be.

******* As usual, thanks for looking, I'll do my best to keep the updates coming.