So I'm bringing this back from the dead. I never got over this vibration. With the latest Covid lockdown up here I've had some time on my hands so I went full science on this. This is gonna be a long one.

I went and setup a Raspberry Pi and hooked up two accelerometers to it via an ADCDAC expansion board. Parts I used were:

RaspberryPi:

https://www.raspberrypi.org/products...-pi-4-model-b/

ADCDAC board:

https://www.abelectronics.co.uk/p/74...xpansion-board

Accelerometers:

https://www.digikey.ca/short/4c5fwj

I then wrote some code to record the vibrations from each sensor:

https://github.com/linds14sr20det/race_car_avc

For the setup to measure this vibration I attached one accelerometer to the transmission (unused bolt hole near the shifter bracket) and the other sensor to the transmission crossmember. My trans crossmember setup uses the 370z mount as it's fluid filled and _should_ dampen vibrations better than any of the other mount solutions, or at least that's what I thought.

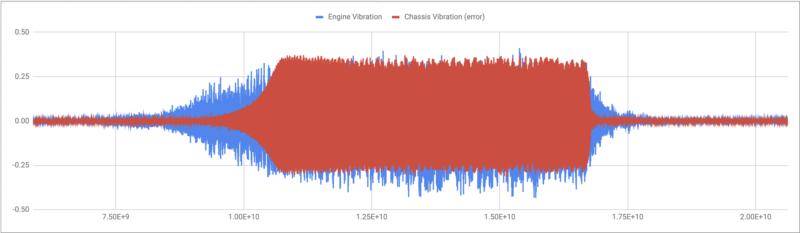

Here's the first graph of engine vibration (blue) vs. chassis vibration (red). This is a recording of me revving the engine slowly from idle to 4500rpm. As you can see engine vibration increases as the rev's rise with not a lot of chassis vibration until you hit 4000rpm when chassis vibrations exponentially increase and are now stronger than the engine's vibration. This is a clear resonance in the chassis. The force the chassis is experiencing here is about 4g's. Considering the trans mount supports over 100 lbs, this is actually a pretty significant force. I wouldn't be surprised if over time this cracked the crossmember or the chassis spot welds.

If you zoom in on the graph you can also see that the vibration occurs at ~150Hz. This works out to the equivalent of 9000rpm (150 cycles/second * 60 seconds/minute), which actually makes sense. 4 cylinder engines are inherently unbalanced with a pronounced second order vibration (vibration at twice engine speed). So this supports a resonance at 4500rpm. Also explains why these trans don't have this problem behind a VQ35 or an inline 6.

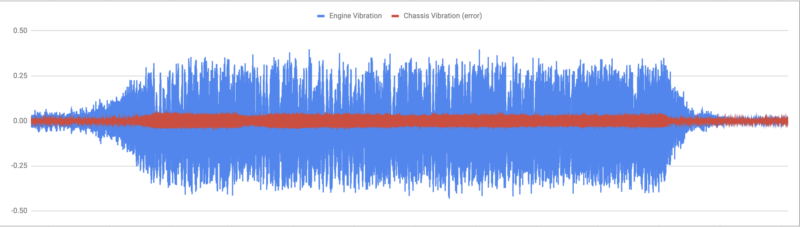

Okay so the next step was to confirm the crossmember is the vibration transfer path. This is easy to do, support the trans on a floor jack, remove the transmission mount, and bolt everything back up. Since the transmission is no longer connected to the crossmember, we would expect to see little chassis vibration if the trans mount is the culprit. If it isn't the source of the vibration we should see no change.

Pretty dramatic decrease. So we know it's the trans mount causing the problem.

There are 3 ways to reduce vibration transfer from all the reading I've now done.

1. Stiffen the receiver (ie. thicker floorpans and a roll cage. This is a street car so nope. Also explains why s-chassis with cages aren't as bad for this vibration)

2. Reduce vibration at the source (Increase the mass of the transmission, add a dual mass flywheel, change the gear mesh patterns, swap to an inline 6, etc. Not gonna do those either.)

3. Soften the engine mount. Vibration elimination has two parts, isolation and damping. Damping increases vibration transmission to the receiver but reduces the peak amplitude. We want to isolate the vibration and to do this we need to soften the engine mount.

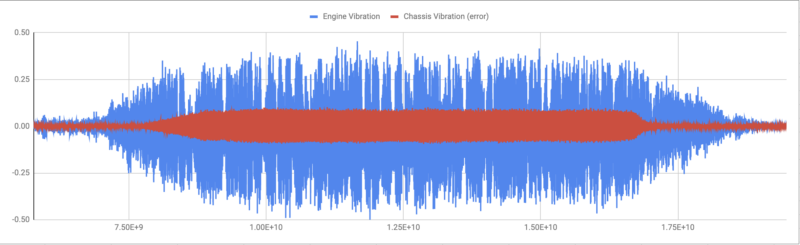

To test this theory, I went and grabbed two valve springs from a vq35de. Since a 4 cylinder second order vibration is only in the vertical direction a spring is a perfect candidate for the mount isolation. This is also how jaguar used to mount it's transmission back in the 70's and 80's so this isn't as hair brained as it seems. Anyways, the VQ35 springs were soft enough they support the weight of the cd009 but compress about an inch each. So I'd ballpark them at a spring rate of 75 lbs/inch. Here's the graph:

We have a winner. Chassis vibration is way reduced and you actually can't feel the buzz or hear the floor resonating anymore. So I'm going to build out a more permanent version of the spring trans mount and report back on it.