After installing my new turbo, I upgraded to taka steel braided lines. The Oil feed from the block would not stop leaking. So like a dumb ass I tried to just wrench it down as hard as I could, because the line was still leaking after I torque the bolt to what the FSM spec ft lbs of torque was 15..

I was getting it tight then, it spun, becoming loose... so I backed the bolt out and to my dismay I had 6 rows of thread wrapped in the thread of the banjo bolt..

Then I could not get the bolt to seat with the copper washers, but then I tried to put the bolt in with out the washers.. and now it seats, but it leeks..

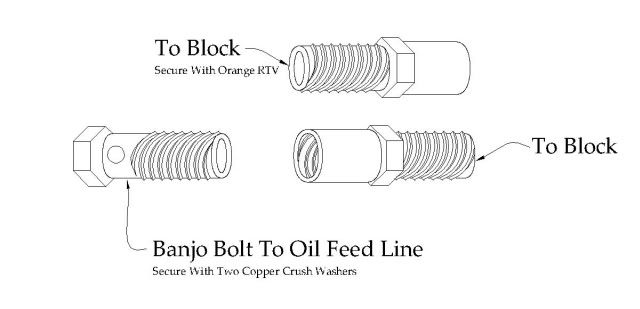

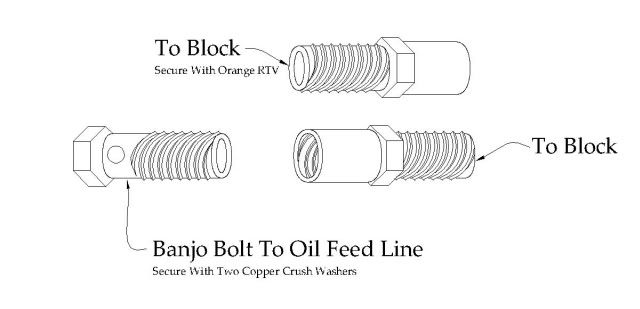

What I came up with was this.. Have a machine shop make me a special "adapter" for this.. Ill give them the banjo bolt as a guide to make this:

im thinking this will work.. what are your thoughts..