|

|

|||||||

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Zilvia Addict

Join Date: Mar 2007

Location: San Francisco

Age: 38

Posts: 756

Trader Rating: (17)

Feedback Score: 17 reviews

|

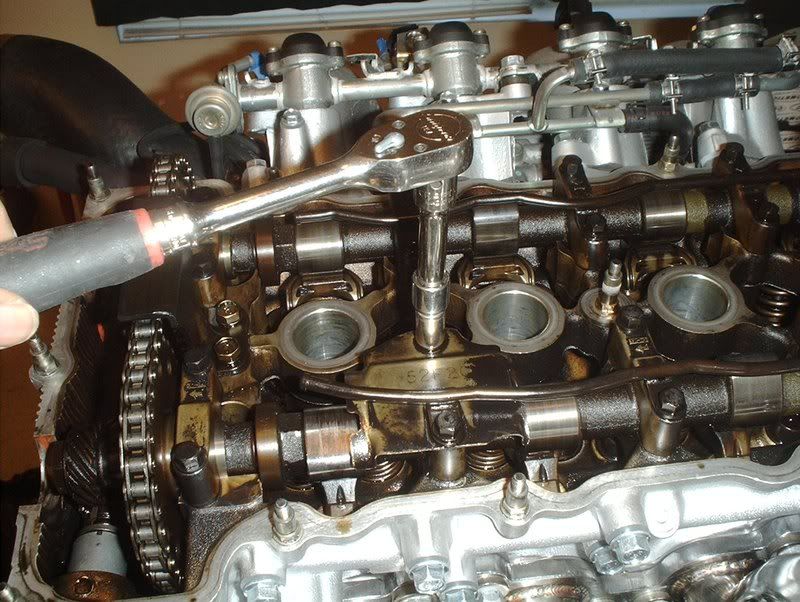

RAS installation broken bolt/stud

So I broken one of these while torquing the bolt/studs.

I know I used a wrong torque wrench that is can not work on a small amount of torque. I'd like to know if KA24DE is using the same stud size so I could get one from the dealer quick. Thanks. |

|

|

|

| Sponsored Links |

|

|

#2 |

|

Zilvia Addict

Join Date: Jan 2007

Location: Melbourne,Australia

Age: 46

Posts: 642

Trader Rating: (1)

Feedback Score: 1 reviews

|

gernally tighten them to around 10-12ft lbs or so or just "wrist" tight with a 3/8" drive

you can get them bolts from nissan but good luck getting the broken "stud" out you can do this with the correct tooling however.... have fun

__________________

|

|

|

|

|

|

#3 | |

|

Zilvia Addict

Join Date: Mar 2007

Location: San Francisco

Age: 38

Posts: 756

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

The bolts were alright when I mistakenly torqued them to ~12 ft/pound, but the first one broke when I decided to re-do them. My torque wrench just gave up on me (I was feeling weird howcome the torque wrench won't click after so many turns). So local Nissans sell studs for SR20 too? Or it is the same size and length as the ones used in KA? |

|

|

|

|

|

|

#4 |

|

Post Whore!

Join Date: Apr 2004

Location: Houston, TX

Posts: 2,701

Trader Rating: (16)

Feedback Score: 16 reviews

|

No idea why people bother trying to torque those studs when the average person doesn't have a wrench capable of reading accurately that low.

Just get a small 1/4" drive rachet and use 5-10 lbs of pressure with a finger or two on the rachet at varying distances on the handle to get a pretty good estimation of the torque.

__________________

S13 Hatch - Goes around tracks quickly DEFSPORT |

|

|

|

|

|

#5 |

|

Zilvia Addict

Join Date: Sep 2006

Location: Billings

Age: 42

Posts: 636

Trader Rating: (8)

Feedback Score: 8 reviews

|

These are probably the most common bolt to break on an SR. Did you get it out yet? They usually come out really easy, I just run a small screwdriver in a circle on the top and they will usually spin back out. The best advice I can give you is to change these all out to studs. You can buy kits to do it or just go buy studs and nuts from ACE. I still run the stock bolts because I have a pile of them but if I have one break again I'm changing to studs.

And as Def said at that low of Tq your better off with just hand tightening it unless you have a really nice Tq wrench. |

|

|

|

|

|

#6 |

|

Zilvia FREAK!

|

THE KA24DE USES THE SAME CAM CAP BOLTS AS THE SR

why is everyone being a dick to him? yeah he snapped a bolt, we all fucking snapepd a bolt. i did the same thing dude. and i got one from the KA. the KA24DE engine uses the SAME EXACT cam cap bolt (it's a bolt, but you called it a stud). i suggest you replace them ALL. the metal was so fatigued on all of mine i replaced them all. |

|

|

|

|

|

#7 |

|

Zilvia Addict

Join Date: Jun 2008

Location: Back in the Bay!

Posts: 619

Trader Rating: (11)

Feedback Score: 11 reviews

|

Go to the dealship like the guys above stated. Snapping those bolts is one of my worse fear when working on the engine. If you're balling, get a set of studs from NAPREC!

|

|

|

|

|

|

#8 |

|

Zilvia Addict

Join Date: Mar 2007

Location: San Francisco

Age: 38

Posts: 756

Trader Rating: (17)

Feedback Score: 17 reviews

|

thanks guys for the well advices.

So i went to Nissans today and ordered the bolts, luckily, I am confrimed that KA uses the same bolts. If it turns out to be not, I will try if the sentra SR will work. However, before i get to use the bolt extractor, I've been drilling the hole for 3 hours. I went to ACE four times already, changing drill bits from general use to hard metal drill bit and changing drill from dremel to 7amp power drill. I'm using 5/64 drill bit as well as 5/64 bolt extractor. BUT the metal of the bolt is just SOOOO hard, the dremel could only get me 1~2mm in for 1 hour straight drilling. I'm now changing to 7amp power drill with hard metal drill bit. I hope I can make this work. Please post if everything looks right so far I'm doing. |

|

|

|

|

|

#9 |

|

Nissanaholic!

Join Date: Feb 2005

Location: Alberta, Canada

Age: 36

Posts: 1,820

Trader Rating: (0)

Feedback Score: 0 reviews

|

You shouldn't need to drill very deep at all. Usually just a couple mm and then use one of those hammer in bolt extractors.

Mine basically spun out by hand. |

|

|

|

|

|

#10 |

|

Zilvia Addict

Join Date: Mar 2007

Location: San Francisco

Age: 38

Posts: 756

Trader Rating: (17)

Feedback Score: 17 reviews

|

It is out!!

tools: 7amp drill DeWalkt DWD112 5/64 hard metal drill bit 5/64 bolt extractor tips: drill with a cold drill bit otherwise it will snap. http://zilvia.net/f/tech-talk/184013...-helicoil.html now, I'm going to hand tighten the bolts or get a really fancy torque wrench! thanks clark for your help over pm  |

|

|

|

|

| Bookmarks |

|

|