|

|

|||||||

| Chat General Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#2 |

|

Zilvia Addict

Join Date: Sep 2006

Location: Billings

Age: 42

Posts: 636

Trader Rating: (8)

Feedback Score: 8 reviews

|

Not too bad, the seats and Bride rails help out a lot. I think if you have seats like my Old Recaro's you may have some troubles. With a helmet I am about 5" away from that bar.

|

|

|

|

|

|

#4 | |

|

Zilvia Addict

Join Date: Oct 2006

Location: barrie, ontario, canada

Age: 38

Posts: 997

Trader Rating: (0)

Feedback Score: 0 reviews

|

If you're welding the cage the proper way. While the cage is still sitting through the floor, you paint the tops... Then finish everything else.

Quote:

Not only to the welds look horrible, I see a crater or two (great place for failures). It also looks like the wind blew the gas away or he forgot to turn it on. (Orange-redish like dust looking stuff). No gas coverage areas are another great place for failures. deposition rates are all wacky as well. Teamsprock. I think you should do some serious practicing. Those welds look really iffy. I would be concerned. If you would like some helpful advice you can PM me. I'd be glad to help you. |

|

|

|

|

|

|

#5 | |

|

Leaky Injector

|

Quote:

yeah sum of the welds do look kinda questionable just didnt wanna bash on any1 but hopefully whenever i save enough for my cage the guy does a good job welding. since ill probably be paying like 2grand if not more for it. its really hard to find a good welder cuz every1 swears up n down they r pro at it lol Last edited by jay pee; 02-17-2010 at 04:22 PM.. |

|

|

|

|

|

|

#6 |

|

Zilvia Member

Join Date: Oct 2007

Location: Vermont

Age: 33

Posts: 287

Trader Rating: (0)

Feedback Score: 0 reviews

|

As far as painting the cage goes, don't use POR15. The stuff smells and will linger in the car for ages. I've been in a caged STI that was POR15'd over a year ago and it still distinctly smells like the stuff.

I used Rustoleum indoor/outdoor gloss black and a regular 1.5" brush. $4.99 for a pint and I covered my entire "6point" cage. No brush strokes, lays out very flat/smooth and looks great. Here's pics of my cage build-up:      dusty...arghhh       Cage finished...finished painting a few hours prior to these pics..      Cage built by Kale's Custom in Essex, VT.

__________________

www.tannermunsondrifting.com |

|

|

|

|

|

#8 |

|

Zilvia Addict

Join Date: Sep 2009

Location: Denham Springs, LA

Posts: 814

Trader Rating: (2)

Feedback Score: 2 reviews

|

I'll be welding in my own cage within the next few weeks, and am really considering going a different route in the backseat of the car (That's right, backseat...). However small and cramped the backseat is, I still want to retain it, as I have a 2 year old little girl that loves to ride in daddy's car. I am going to cage the front similarly to others already here, but instead of an X bar going through the backseat passage to the trunk, I am going to attempt to send a bent one down hugging the rear window, terminating in the trunk on a rear strut tower cross bar. Has anyone seen this done, other than the padded bolt on in the previous page (hypnotiks)? Another huge issue I have with bolt-ins is I am 6'3", and have yet to find a bolt-in that's very friendly to my head room. They all sit too far forward, as mine will be a few inches further toward the rear of the car. I was an engineering major, as well as a welder, as well as an experienced caged builder (I built one in a buddy's 95 wrangler extreme-modified rock crawler). I'm confident that I can bring something new to the table here, but know it's going to take some time, and a hell of a lot of patience, as this is my daily driver. I will keep this thread updated on my progress in huge steps, and will most likely make my own thread showing the build up. Any remarks or tips from experienced fabricators are more than welcome. I have read all tips in this thread, as well as many other builds and fabs (big fan of blu808's creativity and skill).

|

|

|

|

|

|

#9 |

|

Post Whore!

Join Date: Jan 2004

Location: Rohnert Park, CA

Age: 39

Posts: 6,158

Trader Rating: (115)

Feedback Score: 115 reviews

|

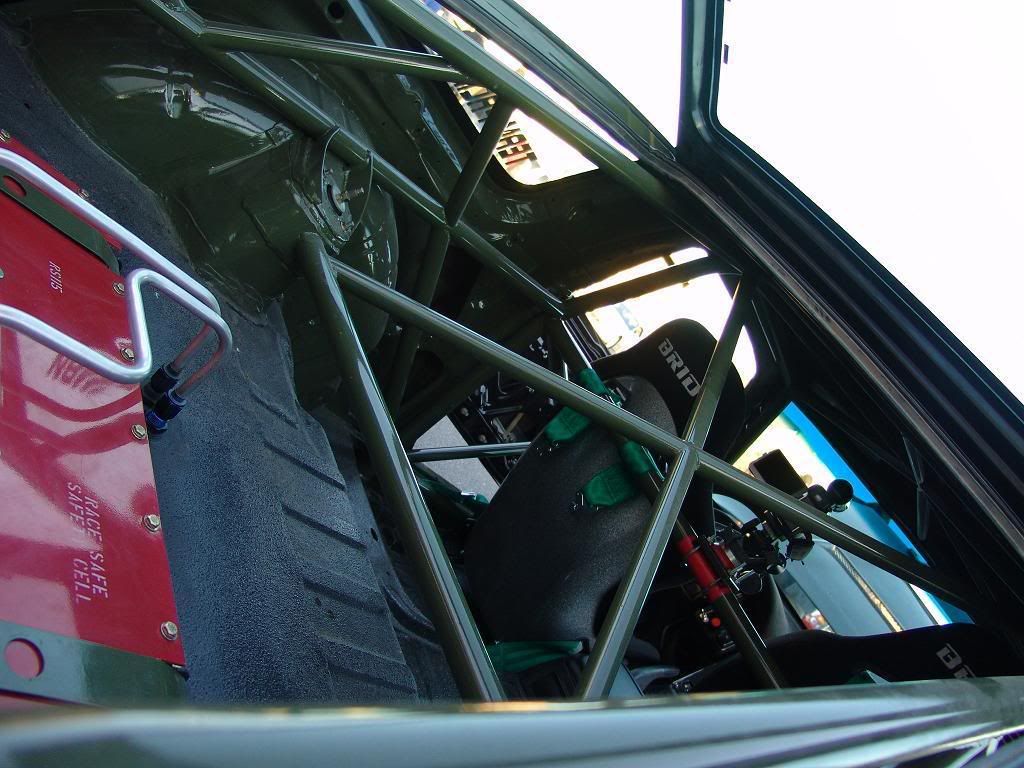

^^ What your intending to do has been done before (on my car

), and I don't recommend it. Bends in the rear down tubes make the cage illegal for FD, SCCA Ect. You can definitely make a strong cage with that design though. My car came with the cage already welded in, so I'm not going to fuck with it, but with the rear bars having bends and the firewall penatration, its not legal for FD or SCCA. ), and I don't recommend it. Bends in the rear down tubes make the cage illegal for FD, SCCA Ect. You can definitely make a strong cage with that design though. My car came with the cage already welded in, so I'm not going to fuck with it, but with the rear bars having bends and the firewall penatration, its not legal for FD or SCCA.Here are some pics.      |

|

|

|

|

|

#10 | |

|

Zilvia Addict

Join Date: Sep 2009

Location: Denham Springs, LA

Posts: 814

Trader Rating: (2)

Feedback Score: 2 reviews

|

Quote:

Either way, I agree with you, your cage appears to be very structurally sound and a strong design. |

|

|

|

|

|

|

#12 |

|

Post Whore!

Join Date: Dec 2002

Location: Campbell, Ca

Age: 42

Posts: 5,010

Trader Rating: (3)

Feedback Score: 3 reviews

|

When I build my cages I double box them. where the tube goes through the top part of the box and is welded to both the bottom box plate and the top box plate.

__________________

|

|

|

|

|

|

#13 |

|

Zilvia Addict

Join Date: Sep 2009

Location: Denham Springs, LA

Posts: 814

Trader Rating: (2)

Feedback Score: 2 reviews

|

update^? and one last question regarding the diagonal bar... Can it be bolted in, rather than welded? I figured I would use a Clevis or some form of it to bolt in the diagonal on track days, once again for the simple reason of keeping a backseat during the week.

|

|

|

|

|

|

#14 |

|

Post Whore!

Join Date: Jan 2004

Location: Rohnert Park, CA

Age: 39

Posts: 6,158

Trader Rating: (115)

Feedback Score: 115 reviews

|

well first and foremost the cage can not penetrate the fire wall and mine clearly does. Second the rules state that the cage must have rear down bars with no bends in them, regardless of the cross behind the driver. Honestly its a fine cage, but if I were to do it myself I would have gone with a more standard design. This has just a bunch of showy parts that weigh extra for no real reason. W/e it was cheap.

|

|

|

|

|

|

#19 |

|

Zilvia Addict

Join Date: Sep 2009

Location: Denham Springs, LA

Posts: 814

Trader Rating: (2)

Feedback Score: 2 reviews

|

That's funny. I looked at the pic before the caption and thought you had made an entire cage out of wrappingpaper tubes and paint tape. Haha. I'll be posting up some pics of progress this weekend!

|

|

|

|

|

|

#24 |

|

Zilvia Junkie

Join Date: Sep 2007

Location: Germany

Age: 38

Posts: 371

Trader Rating: (0)

Feedback Score: 0 reviews

|

very nice...how did you get the dashboard to fit with so little trimming? we're installing a cage in a buddys car tomorrow and i was thinking about how to install the dashboard without cutting the shit out of it...

|

|

|

|

|

|

#25 |

|

Nissanaholic!

|

lechu84 = carlos? friends with david & sennet?

Nicely done. Also want to see how you got the dash in nicely. Firestorm...I don't know if your going to put in a dash bar, but the fabricators that did my cage slipped the tube in the top vent down to the floor. They did absolutely on cutting or trimming on the dash. The only drawback to this is you will NOT be able to remove the dash again, unless you cut/trim it yourself. Which I had to, but I had the front window out, so I just cut straight throw so that I can pull the dash out horizontally. I don't know if that made any sense...lol |

|

|

|

|

|

#26 |

|

Zilvia FREAK!

Join Date: Feb 2004

Location: Houston TX

Age: 42

Posts: 1,245

Trader Rating: (12)

Feedback Score: 12 reviews

|

Heres the cage in my S14, we just finished it up last night. It was done by my good buddy Derrick and fully tigged, now its time to paint the interior.

Last edited by RurouniMidnight; 03-22-2010 at 11:43 AM.. |

|

|

|

|

|

#29 |

|

Zilvia Addict

Join Date: Sep 2006

Location: Billings

Age: 42

Posts: 636

Trader Rating: (8)

Feedback Score: 8 reviews

|

Thanks for the comments on my cage, I appreciate the concern. I did not weld this, If I did there would be lots of reason for concern since I suck at welding. I had it inspected by the local NHRA inspector and he went through a pretty thorough inspection and said it looked great. Most of the professional welders who have seen it in real life have also said the same. The color looks much worse because I was taking pictures in my garage with long exposures and cheap flood lights. But I appreciate your concern and will look more into it. I have had a few of the really well known welders on here tell me it looked great so I was pretty happy but if I should be concerned I will have more people inspect it and see if I need something done to correct it. Before the door bars were finished it was certified to go 8.50's. The door bars are just being finished as this obviously is not a drag car. Again thanks for the concern and I will have a close friend who has been welding for 30+ years stop by and look at it and see what he thinks.

|

|

|

|

|

|

#30 | |

|

Zilvia Addict

Join Date: Oct 2006

Location: barrie, ontario, canada

Age: 38

Posts: 997

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

Again. I'm not trying to come off as a dick. I'm offering my opinion as a professional certified TIG welder. And by the standards that I set for myself. (Also going back to school to start my weld inspector training this Nov) 7.4.2 of this years FD rule book. (I believe this also covers D1 or whatever?) I know we use these rules for DMCC (Drift Mania Canadian Championship) Welding shall conform to American Welding Society D1.1:2002, Structural Welding Code, Steel Chapter 10, Tubular Structures. Based on those standards I would reconsider those welds. Again. This is just my opinion. And I'm NOT trying to come off as an arrogant asshole. Just trying to state my thoughts in a friendly professional manner, lol :P |

|

|

|

|

|

| Bookmarks |

|

|