|

|

|||||||

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#121 | |

|

AFC #1

Join Date: Oct 2003

Location: 昨晩あなたのお母さんの家

Posts: 20,181

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

I drilled and taped my turbine inlet years ago. Have a PLX R-500. Who knows the quality of the probe. Haven't had a problem since. Granted it doesn't see the track as often as you guys.

__________________

Comments should be taken as Opinions not as Statements of Fact

|

|

|

|

|

| Sponsored Links |

|

|

#122 |

|

Zilvia Member

|

That would make sense, I think I read in maximum boost or some other turbo book that only about 25% of the energy to spin the turbine comes from the kinetic energy of the exhaust gas pulses. The rest of it comes from turning heat energy in the exhaust stream into kinetic energy due to (paraphrasing here) the magical snail shape of the turbine housing.

If MOST of the energy to spool the turbo comes from heat, then it would make sense that a much higher temp is seen pre-turbine, and that the difference between pre-turbine and post turbine temps gets larger when you're in boost and the compressor is asking the turbine to do more work.

__________________

'95 240 | @SleepySteve72 |

|

|

|

|

|

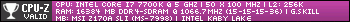

#123 | ||

|

Post Whore!

Join Date: Apr 2004

Location: Houston, TX

Posts: 2,701

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

Quote:

You can see how much hotter the manifold and turbine housing is vs. the outlet housing is in my pic. That's because the engine is not cruising, it's either in boost, or braking (low flow). So the delta T is high across the turbine at all times.

__________________

S13 Hatch - Goes around tracks quickly DEFSPORT |

||

|

|

|

|

|

#124 |

|

Post Whore!

Join Date: Apr 2006

Location: bangin on my chest Account: BANNED #fucksupreme

Age: 82

Posts: 5,932

Trader Rating: (3)

Feedback Score: 3 reviews

|

sorry def, i just dont have the mental capacity to understand thermodynamics, physics, or most types of basic math. i flunked pre-algebra a couple times. mostly because i was distracted by my math teacher's panties. merry xmas mofos |

|

|

|

|

|

#125 |

|

Nissanaholic!

Join Date: Aug 2013

Location: Denver

Age: 40

Posts: 2,052

Trader Rating: (14)

Feedback Score: 14 reviews

|

So, I am bringing this from the dead with this video:

Mostly an ad for nordlock, but informative non-the-less.

__________________

S13 Vert | SR | PE1420 | 5-Speed | 15x9.5 - 0 |

|

|

|

|

|

|

#126 |

|

Nissanaholic!

Join Date: Aug 2010

Location: Under a rock

Posts: 2,264

Trader Rating: (43)

Feedback Score: 43 reviews

|

I really like NordLock washers, they worked great on all my SR setups. One issue is the thickness through, which you really can't get away from and will end up with issues like I had on my GTR. I ended up swapping the NordLock for some copper nuts because I just wasn't super confident with the lack of threads with the washers.

|

|

|

|

|

|

#127 | |

|

Post Whore!

Join Date: Dec 2004

Location: Poconos, PA

Age: 39

Posts: 8,030

Trader Rating: (58)

Feedback Score: 58 reviews

|

Nordlocks work great, and you probably would have been ok in that example.

I've found best luck with new OEM studs and nuts on the manifold, along with the Z32 locking tabs. ON the turbine outlet however I've moved onto the porsche/vw copper deformed thread nuts. Quote:

__________________

Want Air Conditioning in your SR20 Swapped car? Check out www.sr20acbrackets.com for more information! Quest Alternator Conversions for SR20! Check my Group Buy! Tired of lousy internal gates? Go external wastegate with one of my manifolds, Check out my group buy |

|

|

|

|

|

|

#128 |

|

Zilvia FREAK!

Join Date: Jun 2010

Location: Toronto, ON

Age: 36

Posts: 1,182

Trader Rating: (0)

Feedback Score: 0 reviews

|

I've also had good luck with this combination after 5 seasons of track days. I did however have a stud break at the turbine outlet. It was just a regular one from the hardware store. I would have been better off using OEM studs or aftermarket inconel.

|

|

|

|

|

|

#129 |

|

Post Whore!

Join Date: Dec 2006

Location: Misawa, Japan

Posts: 6,815

Trader Rating: (8)

Feedback Score: 8 reviews

|

On my RB26 Build Ill be using a Combo of Prevailing Torque Nuts and OEM Locking Tabs for the T2 flange and oversize serrated Flange nuts for the elbows.

(Nothing Torqued down yet)  Never had an issue with the stock hardware on my SR in the past 9 years of beating on it. Decided to upgrade as an extra preventive measure since the RB26 is not space friendly.

__________________

後輪駆動車1番 後輪駆動車1番1989 Built SR GT2871R -363whp 1998 S14 W/RB25- 250ish (For Now) 1986 SR86 - 200ish 1990 R32 GTR - 320hp Don't Buy Engines from JDM-Online http://zilvia.net/f/businesses/207457-jdm-online.html Don't Buy XS-Power or SSAC Shit |

|

|

|

|

|

#130 |

|

Nissanaholic!

Join Date: Aug 2011

Location: France - Toulouse

Age: 43

Posts: 1,851

Trader Rating: (0)

Feedback Score: 0 reviews

|

Just use Vband clamps everywhere ... seals better, no gasket, no stud, no drama. This was not available before, now it is an option on every quality turbo / manifold.

|

|

|

|

|

|

#131 |

|

Post Whore!

|

...........Or just use stock Inconel hardware ($2.53 per stud), nordlock (30 shipped) and PROPERLY secure the downpipe.

Once I redid my downpipe and installed a stronger than stock hanger, I have had ZERO issues with blowing gaskets (did 8 or 9 track days on this setup with nary an issue). I removed the system this weekend and there were zero signs of exhaust gasket compromise. It actually still has the stock sheen from being new. This also included one track day with 100+ degree outside temps for the entire day. In addition, the turbine outlet sees much less temp than the turbine inlet, so non exotic hardware works just fine in that capacity. |

|

|

|

|

|

#132 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 41

Posts: 4,828

Trader Rating: (17)

Feedback Score: 17 reviews

|

I've had no problems using OEM hardware on any past 240sx, you just need to get all the support brackets exhaust hanger brackets proper. Think about it, you can buy a brand new or low mileage silvia which has all oem parts and drive it 100 or 200k without taking out the engine to fix the exhaust gaskets every 20k like we all pretend

For EGT on a stock location t25 flange definitely put it at the outlet (after turbo). Reasons: 1. you might want to remove it at some point 2. putting extra holes in anything scares me 3. tap a O2 sensor bung so you can take the EGT sensor out whenever you want and plug the hole without worrying about leaks. You could also use it for a narrowband. Widebands need to be well away from the turbo but the narrowband is fine to use right there at the outlet. 4. speaking of which, the hole is already there. OEM outlets have a sensor hole we use for EGT, then go back to the narrowband when done. |

|

|

|

|

|

#133 |

|

Post Whore!

Join Date: Sep 2004

Location: Independence, Ore.

Age: 39

Posts: 2,711

Trader Rating: (24)

Feedback Score: 24 reviews

|

^You are also just street driving an SR with a 5k rev limit or whatever. Apples to bananas comparison in terms of use.

My stage 8 fasteners seems to be working well -- survived a few track days and haven't had any issues. Took everything apart a few months ago and it all looked brand new, still. Re-did the t2 gasket anyway because I had a few extra gaskets laying around. For the turbine side, I quit using the distortion-head stuff and I just use stainless nuts and lock washers instead. Easier to pull apart and the nut never galls to the point where it pulls the stud out with it. |

|

|

|

|

|

#134 | |

|

Post Whore!

|

Quote:

Placement of the EGT in the turbine outlet does not give accurate engine exhaust temperatures. The turbine itself acts as an absorber and heat sink. Look up Laws of thermo. The whole point of the EGT is to measure the temperature of the unabated A/F mixture from the ENGINE not the TURBO, and any impingement from an outside source (gases expanding over the turbine wheel and loses to the turbine housing) will cause inaccurate readings. To Kingat0n 1) EGT probes are designed to withstand hundreds of thousands of heat cycles with peak temps over 1800 F (at which point you have a litany of other problems). It does not need to be removed constantly 2) Fair opinion 3) EGT and O2 bungs are two completely different sizes. The EGT is a probe. The O2 sensor is not 4) Incorrect. The OEM outlet has two provisions (for the S13) for EGR and O2. No OEM SR20DET has any provisions for EGT (especially considering the ECU itself has not provisions to actually read and adjust abased off Exhaust Temps). |

|

|

|

|

|

|

#135 | |

|

Post Whore!

|

Below is a proper quote to show just how DRASTIC a difference it mounting the EGT before and after the turbo

Taken from EGT Measurements pre and post turbine Quote:

|

|

|

|

|

|

|

#136 |

|

Nissanaholic!

|

Awesome info, thanks dude!

__________________

MRP Manufacturing |

|

|

|

|

|

#137 | |||

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 41

Posts: 4,828

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

Quote:

Heres how that went down: Pros of tapping manifold for EGT: more accurate read Cons of tapping manifold for EGT: Still not sure of placement (WHERE in the manifold is ideal? Is it close enough to a particular valve or cylinder that runs hotter than the rest?), Extra hole my exhaust system to leak from, daily driver that needs to go 100k+ miles so the chances of something loosening up by itself like this is greater, don't want to worry about an extra sensor, Would like to be able to remove it easily and not leave behind a hole. Is there even a plug capable of blocking a hole I make in the manifold? I dont think a typical alum/brass 1/8" npt plug would work there. Also, what if you screw up making the hole or tapping it? Rip all the threads out of it or put it in sideways is a real possibility. Just decided I didn't want to deal with all that extra possible nonsense on an already almost antique engine which sees only light duty. Quote:

1) EGT probes are designed to withstand hundreds of thousands of heat cycles with peak temps over 1800 F (at which point you have a litany of other problems). It does not need to be removed constantly Response: Lots of cough* nissan owners are cheap, and use $30 ebay EGT gauges. cough cough. Those gauges could just... oh I dont know... stop working. And if you tapped your manifold, oh dear lord now you have all this extra crap running all over the place with all the other crap, and it doesn't even work anymore. IMO save yourself the hassle... if you don't really know how to use one or even sure if you need one, the last thing I want is a hole in my exhaust manifold. 2) Fair opinion 3) EGT and O2 bungs are two completely different sizes. The EGT is a probe. The O2 sensor is not Response: You buy an O2 plug and tap that. One day, when your $30 gauge quits, just replace it with an O2 sensor. *THINK* 4) Incorrect. The OEM outlet has two provisions (for the S13) for EGR and O2. No OEM SR20DET has any provisions for EGT (especially considering the ECU itself has not provisions to actually read and adjust abased off Exhaust Temps) Response: I mean the hole for the O2 sensor. Just buy a plug and tap that for the EGT sensor is what I meant. If using a $30 gauge on an OEM manifold in a daily driver, this is adequate. I can tell that when I pull 5* of timing off the top of my cruise, my EGT moves 30-50*F hotter, so for the sake of argument lets just say it does exactly what it needs to do in my application. Last edited by Kingtal0n; 01-10-2016 at 07:39 PM.. |

|||

|

|

|

|

|

#138 | |

|

Zilvia Addict

Join Date: Apr 2011

Location: Near Pittsburgh, PA

Posts: 637

Trader Rating: (1)

Feedback Score: 1 reviews

|

Quote:

|

|

|

|

|

|

|

#139 | |

|

Post Whore!

Join Date: Dec 2004

Location: Poconos, PA

Age: 39

Posts: 8,030

Trader Rating: (58)

Feedback Score: 58 reviews

|

Quote:

I think the last Mike's car ran was just before he did that...haha :P

__________________

Want Air Conditioning in your SR20 Swapped car? Check out www.sr20acbrackets.com for more information! Quest Alternator Conversions for SR20! Check my Group Buy! Tired of lousy internal gates? Go external wastegate with one of my manifolds, Check out my group buy |

|

|

|

|

|

|

#141 |

|

Zilvia Junkie

|

Bump for more discussion,

I think I've blown about every gasket on turbo exhaust after some serious track abuse. Turbo to manifold, Manifold to elbow, Elbow to downpipe, So after reading 5 pages, I have no conclusion. Im not going to weld my manifold to turbine house, Im not going to tack weld the nuts/studs. What IS the best proven solution here? |

|

|

|

|

|

#142 |

|

Post Whore!

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 33

Posts: 7,721

Trader Rating: (10)

Feedback Score: 10 reviews

|

I still stand by welding the turbine housing to the manifold. I'd rather replace it with a new sub $200 housing if I want to sell the turbo by about the second time I replace the gasket...

Funny you bumped it I was just reading through this whole thread yesterday lol. |

|

|

|

|

|

#143 |

|

Zilvia FREAK!

Join Date: Jun 2010

Location: Toronto, ON

Age: 36

Posts: 1,182

Trader Rating: (0)

Feedback Score: 0 reviews

|

See my post above (#128). I've great great luck with the new locking tabs and stock hardware at the turbine inlet. And new studs and stover nuts at the turbine outlet. 5 years of tracking, never had any hardware come loose.

|

|

|

|

|

|

#144 | ||

|

Post Whore!

Join Date: Apr 2006

Location: bangin on my chest Account: BANNED #fucksupreme

Age: 82

Posts: 5,932

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

Quote:

all things considering, i now have 3 turbo projects pending so i'll try to post if i ever get something concrete to add here |

||

|

|

|

|

|

#145 |

|

Zilvia Addict

Join Date: Jan 2013

Location: Virginia

Age: 32

Posts: 622

Trader Rating: (9)

Feedback Score: 9 reviews

|

Back from the dead!

Hate to bump an old thread but I'm curious if anyone's had any luck using copper gaskets in the turbo to manifold location? I know that some of the professional import drag teams run copper in place of MLS between the turbo and manifold on super high boost applications but their cars don't see the sustained high temperatures that ours do. I'm looking specifically at the SCE offerings like this:  I do mostly drifting but still manage to burn through at least one gasket a season and I can only see it getting more frequent now that my friend has talked me into doing some actual lap days this year. My exhaust is solidly mounted and I run a flex section so it seems like heat is the main factor that's causing the failures. I'm redoing my current turbo setup and my plan is to have the mating surfaces on my manifold machined smooth/flat and run a copper gasket. I also found some ARP manifold studs and copper nuts in the garage that I'll probably run in place of the OEM hardware. I figured I would check in and see if anyone's had any luck with something similar before I end up having to pull the manifold again in a couple months... |

|

|

|

|

|

#146 | |

|

GM2 (SW/AW)

|

Quote:

I'd actually like to hear some feedback on these as well. Without doing any research, I'm not sure what the benefit is supposed to be, The rapid cooling capabilities of copper? Because it surely copper will melt at a lower temp than the MLS or thing solid metal gaskets. I've never actually had one of these blow out on me. The only time a had a manifold gasket failure (either turbo side or head side) was because a bolt/stud backed out ever so slightly causing a loss of constant pressure on the gasket. In for some first hand knowledge.

__________________

Quote:

KA-T for life! Current for sale advertisement  |

|

|

|

|

|

|

#147 |

|

Zilvia Addict

Join Date: Apr 2011

Location: Near Pittsburgh, PA

Posts: 637

Trader Rating: (1)

Feedback Score: 1 reviews

|

Upgrade turbo to manifold bolts one size.

Upgrade to Stage 8 hardware. Done. Stage 8 hardware can be annoying but I haven't had a problem. Removing it is pretty easy with a small flathead... Just pull all the clips and triangles first, then loosen the nuts. |

|

|

|

|

|

#148 | |

|

Post Whore!

Join Date: Apr 2006

Location: bangin on my chest Account: BANNED #fucksupreme

Age: 82

Posts: 5,932

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

all these years and there is no discussion other than this thread when it comes to the oil restriction in the turbo plumbing. Until today. Years later, I needed another bolt for another car I am building. The above photo speaks for itself, the restriction is inside the BLOCK-SIDE banjo bolt. Not the hard line, not the turbo oil banjo... the BLOCK-SIDE (M12x1.25). And, according to Juan, SAME PN for S13/S14/S15... so the restriction is all the same, about 1.5mm... Wow, this was a lot more headache than it was worth. |

|

|

|

|

|

|

#149 |

|

Post Whore!

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 33

Posts: 7,721

Trader Rating: (10)

Feedback Score: 10 reviews

|

Turbo & Manifold Hardware Discussion

That wouldn't make sense as the bb t28 needs the restriction that the journal bearing turbos don't have. So why would it have same PN, same 1.5mm hole across all three?

Sent from my iPhone using Tapatalk |

|

|

|

|

|

#150 |

|

Post Whore!

Join Date: Apr 2006

Location: bangin on my chest Account: BANNED #fucksupreme

Age: 82

Posts: 5,932

Trader Rating: (3)

Feedback Score: 3 reviews

|

as garrett states on their site, both turbos, journal or bb, require a reasonable amount of pressure that needs to be measured at the turbo.

WITH the factory hard lines AND the factory banjo bolt (restricted, shown above) - nissan most likely was happy with the amount of oil pressure at the turbo. i think the problem exists when people run larger oil supply (flex lines) such as 4an, due to ease of availability & lower cost. on the miata i am building, i bent my own hard lines using 3/16 tubing (3an fittings) and no restrictor at all. i am pretty confident that this should suffice with the sr20det t25 journal bearing turbo. |

|

|

|

|

| Bookmarks |

|

|