|

|

|||||||

| Chat General Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Leaky Injector

Join Date: Jul 2003

Location: Fallbrook, CA ....i love this place

Age: 40

Posts: 126

Trader Rating: (0)

Feedback Score: 0 reviews

|

MyBuildup. stich weld wire relocation

Haven't had a license in a long time so i have time to work on the car. I decided to stitch weld as much as i could and the tedious work of removing most of the unnecessary wiring, and relocating it. the two main fuse boxes that are in the engine bay have been relocated to the inside of the car.

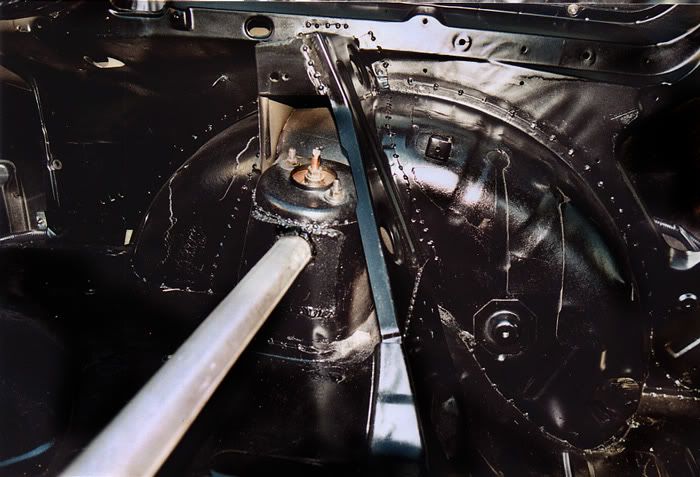

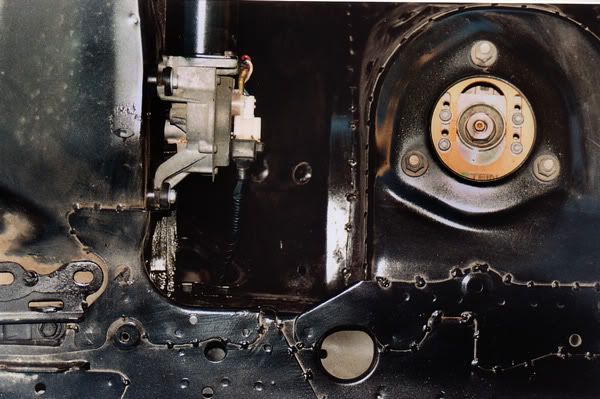

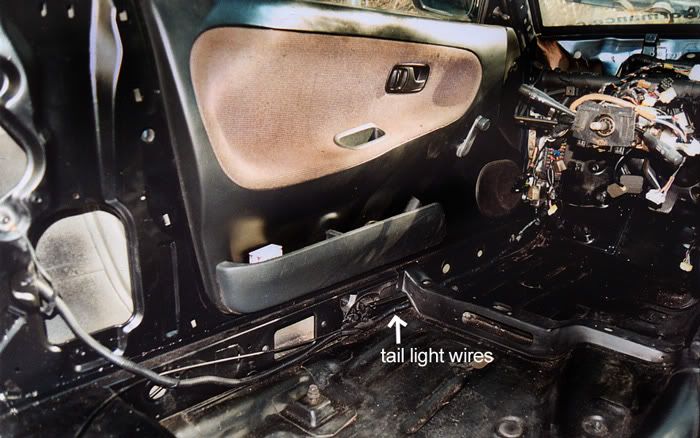

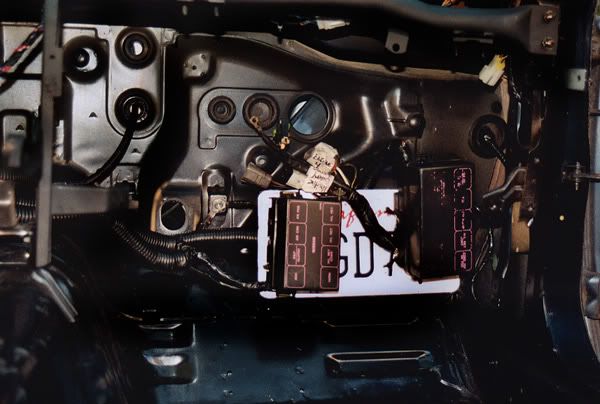

list of eliminated wires include... door jam light stuff, dome light, power seat belts, anything that controls the air circulation cause that has all been removed also, horn blah blah pretty much anything that doesnt control the engine or tail and headlights. oh but i still have my stereo stitch weld stuff.        electrical stuff  these are all the wires left that run to the back of the car. no more huge mess  these are the only wires that run into the engine bay. the harness is small enough that i wont have problems on rubbing so i still ran it through here.  engine bay wires end over here at the passenger headlight.  fuse boxes that are usually near the battery and under the intake box. im going to extend the plugs off the engine harness and they will be fed into that big hole above the bundle of plugs. this area still needs to be cleaned up a little. and i need to extend some stuff for the battery that will be behind the passenger seat.  windshield wiper harness now runs in through here instead of over the wheel through the fender well.  overall shot... some things still need to be cleaned up. most dangling plugs you see are buttons on the dash for headlights. gauge cluster and stereo  older shot. all i want is stock silvia sideskirts as far as exterior goes  my garage. This car is still staying na-KA for now. no fancy engine stuff goin on. engine bay will just be really simple.

__________________

hi. |

|

|

|

| Sponsored Links |

|

|

#12 |

|

Post Whore!

Join Date: Nov 2004

Location: North Korea

Posts: 14,579

Trader Rating: (27)

Feedback Score: 27 reviews

|

http://www.shopmaninc.com/foam.html

That's the foam they are talking about. There is another place in your area that sells it, the name is slipping my mind at the moment.

__________________

|

|

|

|

|

|

#13 | |

|

Leaky Injector

Join Date: Jul 2003

Location: Fallbrook, CA ....i love this place

Age: 40

Posts: 126

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

__________________

hi. Last edited by FallbrookS13; 01-10-2006 at 05:43 PM.. |

|

|

|

|

|

|

#18 | ||

|

Leaky Injector

Join Date: Jul 2003

Location: Fallbrook, CA ....i love this place

Age: 40

Posts: 126

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

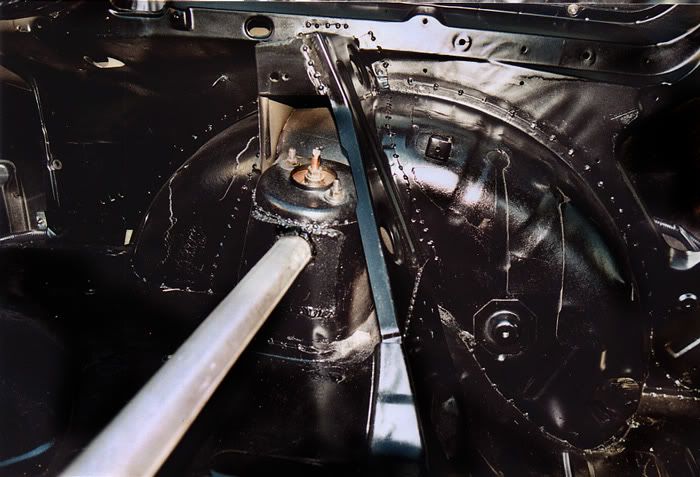

for the seams i just used a heavy duty wire wheel and a hand chisel and just went out it. this is definitely the most tedious part of the project. there is a pretty huge layer going around the bottom of the rear shock towers. I also cleaned the metal with acetone after that. some day im gonna get a good paint job and at that time ill strip everything and get the whole car sprayed inside and out. but for now its just rattle can... like the exterior of my car.  Quote:

you can see that in this pic

__________________

hi. |

||

|

|

|

|

|

#20 |

|

Zilvia FREAK!

Join Date: Apr 2005

Location: somewhere north of mexico

Posts: 1,538

Trader Rating: (3)

Feedback Score: 3 reviews

|

Drew you can do my engine bay harness....

-Aaron

__________________

feel the rythym. feel the ride. get on up. it's bobsled time. COOL RUNNINGS!!!  formerly sideviewcivic Save a Horse. Drift This Cowboy. AirBag Club Member #0014

|

|

|

|

|

|

#22 |

|

Zilvia Member

|

Looks great! You did a lot more spots then I did with my brothers Corolla. He wants a cage in there later on, so I just put a stitch inbetween every existing spot weld, untill he gets use to the car, no further chassis work will be done for him... I'll do more once he is comfortable driving it.. Chassis prepping is a bitch, but its all worth it at the end of the job. You get to look into how much effort you put in. The s13 chassis also has a lot more seam and area to stitch. Are you going to remove all the glass and stitch around the door frame and other chassis area? Also great job on relocating the wires, its going to be sick once its all done.

|

|

|

|

|

|

#23 |

|

Leaky Injector

Join Date: Jul 2003

Location: Fallbrook, CA ....i love this place

Age: 40

Posts: 126

Trader Rating: (0)

Feedback Score: 0 reviews

|

ill do the more extensive welding later down the road when i get a really good paint job. strip the whole car down again and paint everything inside and out professionally. this was just the result of spare time on my hands

__________________

hi. |

|

|

|

|

|

#27 |

|

Post Whore!

Join Date: Jan 2004

Location: Rohnert Park, CA

Age: 39

Posts: 6,158

Trader Rating: (115)

Feedback Score: 115 reviews

|

did you just weld it in a sequence or did you go sparatically arround the car. I heard that the heat from welding can actually warp the car. You susposta do it on pinchweld stands to keep the chassis true. Looks nice.

|

|

|

|

|

|

#28 |

|

Zilvia Member

|

Keeping the chassis on the ground with all 4 wheels is more then good enough. Just to keep it on the safe side, you can just go sparatically around, but there isn't much heat really from one stitch. They also cool off fairly fast.

|

|

|

|

|

|

#29 |

|

Leaky Injector

Join Date: Jan 2004

Location: Jacksonville,FL

Age: 37

Posts: 122

Trader Rating: (0)

Feedback Score: 0 reviews

|

Have you ever done it?

It really heats up the metal. If you weld in a line it will get the panel extrememly hot. Maybe when I did it I didnt have the welder setup right or something. |

|

|

|

|

|

#30 |

|

Leaky Injector

Join Date: Jul 2003

Location: Fallbrook, CA ....i love this place

Age: 40

Posts: 126

Trader Rating: (0)

Feedback Score: 0 reviews

|

no i didnt cut the harness. i unplugged the relays so it could fit through the firewall then put them back in the box

as far as the stitch weld goes. i think its good to do it on just a really level ground. not on jack stands or anything. i would assume that you would want the car loaded in the same situation as it would be while driving. on jack stands or some other rig the car would be potentially unevenly loaded. who knows though. thats my theory and is what i went with. i would do half a seam then move to a different area of the car. it is a good idea to jump all around the car and do bits and pieces here and there. like half the front shock tower left . then half the rear right then half the front right half the rear left then go finish them up in that order. as for long seams. . do a few spots at the beg. then the end. then the middle then just progressively close it all up and i mean also this is just a backyard built car. no budget or anything backing it. just me fuckin around with shit. its also just a track beater so its something that is pretty expendable. not some time attack or jgtc car where every minute detail could potentially draw gains. i just stitch welded it to obvious stiffen things up and the car is in good frame condition now and i wanted to tighten it up more. cause as the years go by and you drift and hit up track events more and more the car just gets tired and not as responsive as it was years ago

__________________

hi. |

|

|

|

|

| Bookmarks |

|

|