|

|

|||||||

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Zilvia FREAK!

Join Date: Mar 2003

Location: Miami

Age: 41

Posts: 1,590

Trader Rating: (7)

Feedback Score: 7 reviews

|

Ive got a v8 bro (450sx part 3)

Back story...

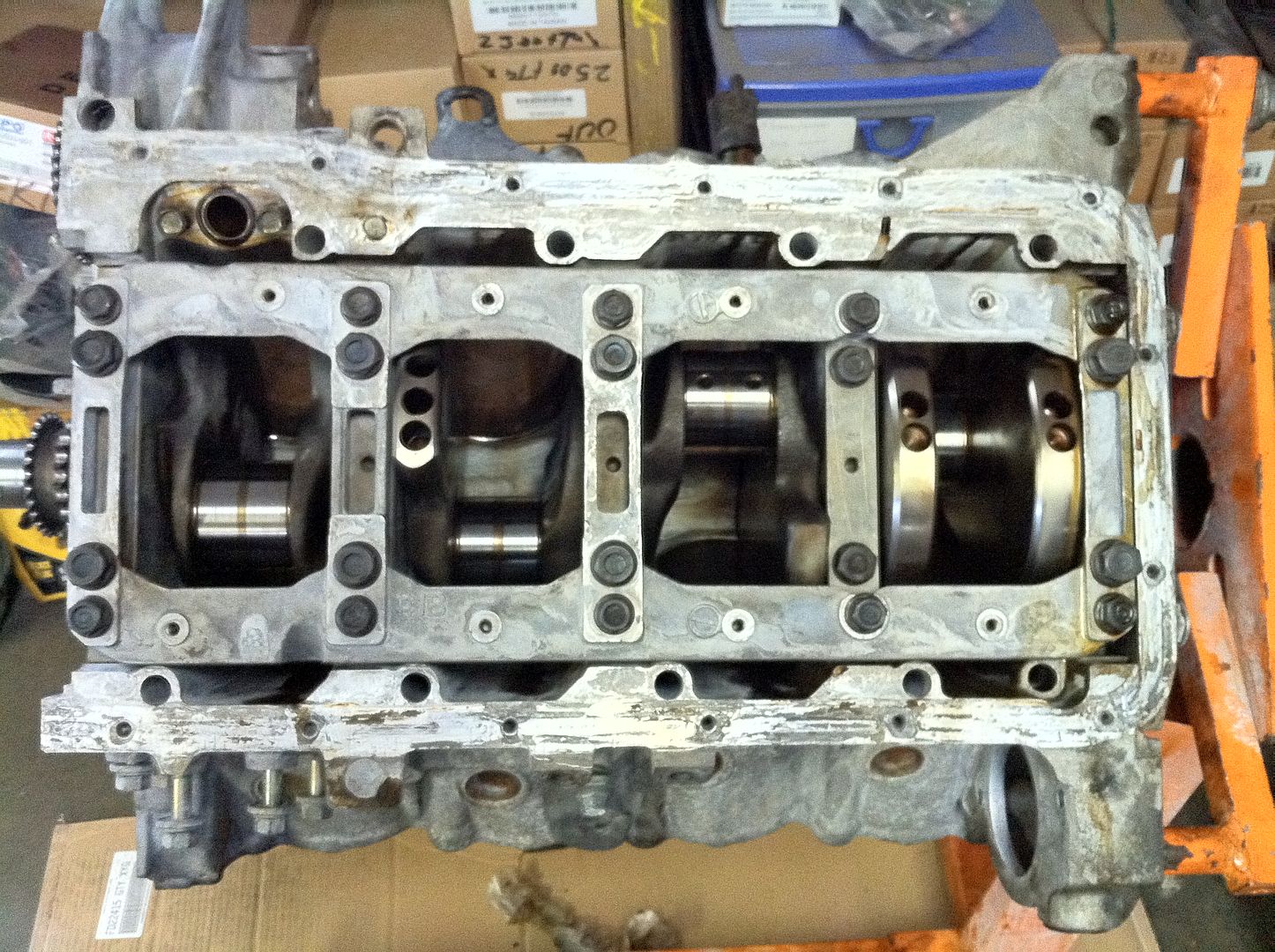

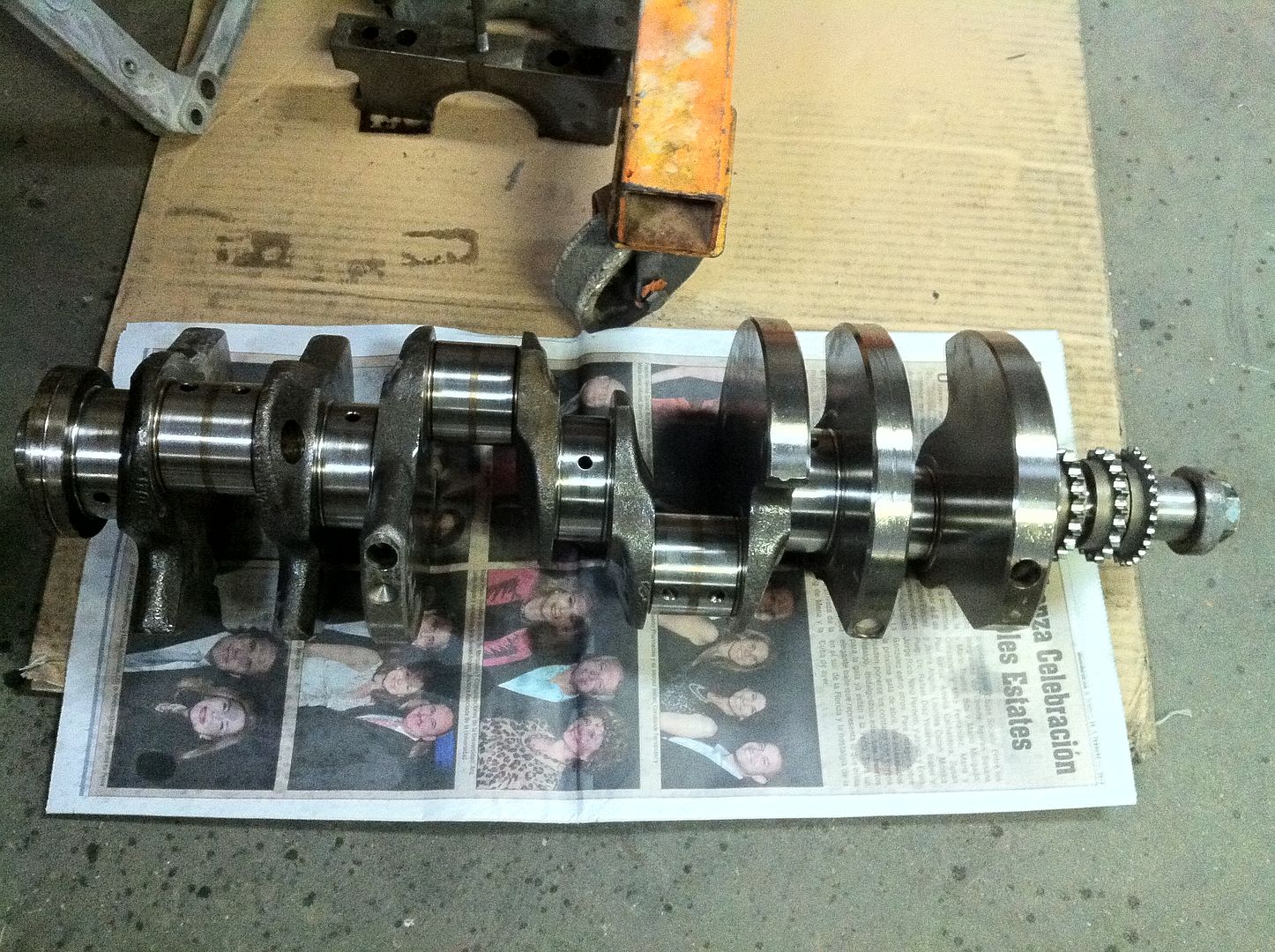

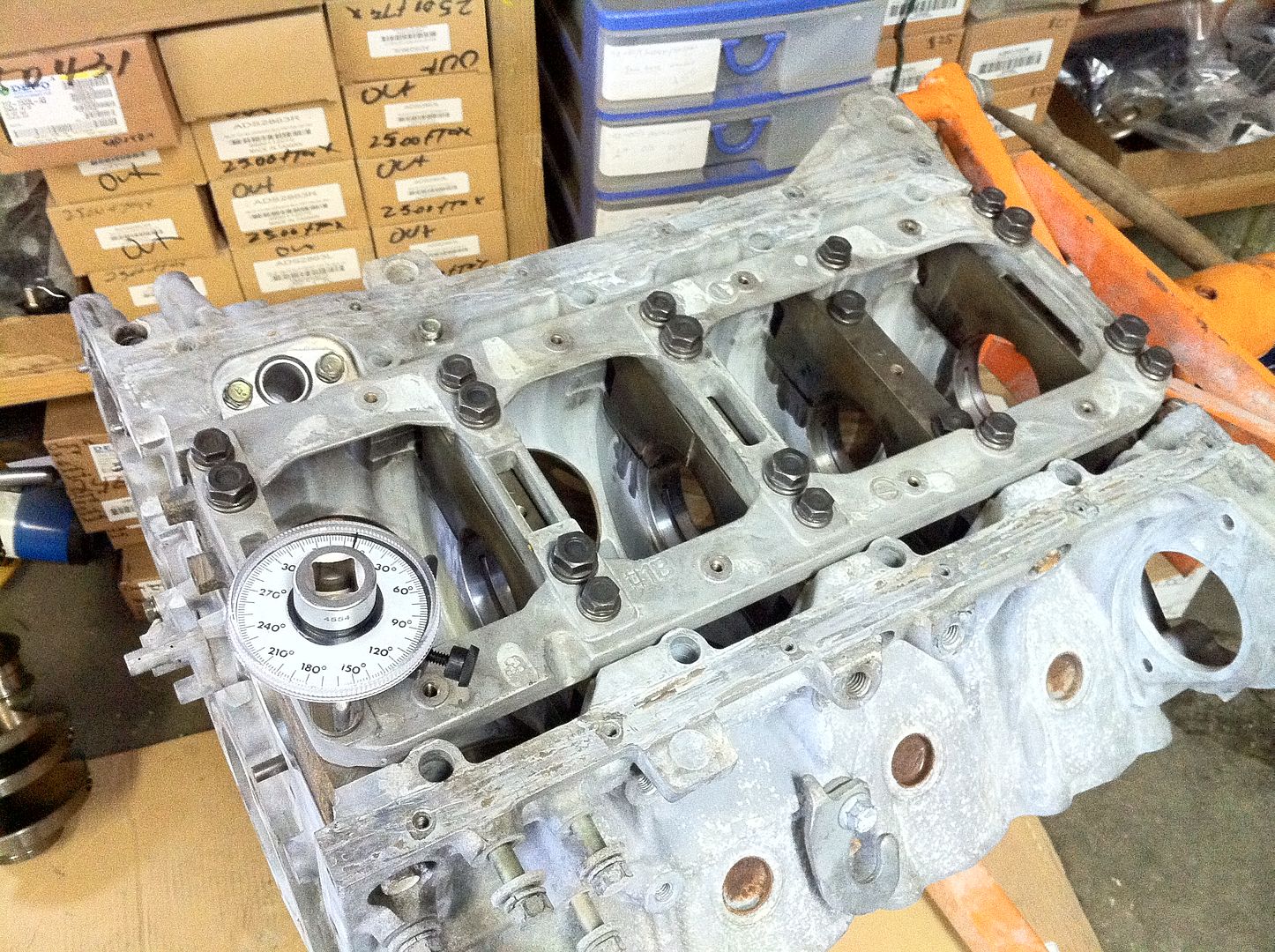

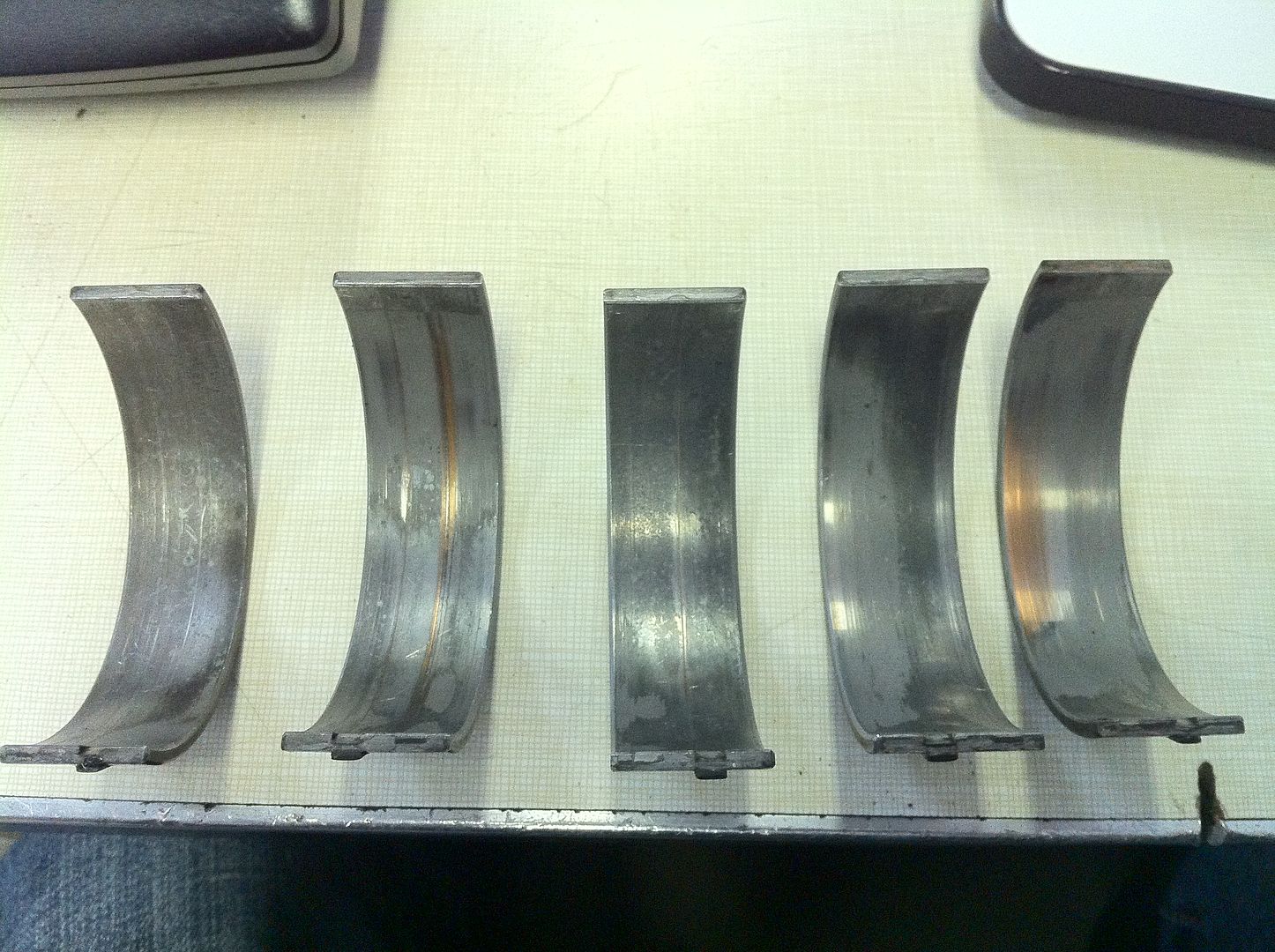

Well the current vh45de has done me well, its been running for almost 3 years, supercharged for about 2 years. It has close to 5000 track miles and still running strong. About 2.5 years ago i bought a set of one of mazworx vh45de heads with custom cams, custom super tech valve springs and titanium retainers with the expectation that when the motor let go id take it out and build it using the heads. Fast forward today, heads have been on the shelf 2.5 years, and i decided to just build one of my spare motors and when I'm done retire the old one. Goals are to be able to open the clearances in the bottom end and be able to rev it out to at least 8-8500 rpms and if it make enough power remove the supercharger and leave it N/A. Here are the pics and progress so far...... Took 1 of my 5 spare motors and had one of my guys pull the heads and clean it so i could disassemble it in the office.   its a 160,000 miles, series 2 motor, that ran before we pulled it... ewww dirty.  on the stand ready for cleaning..    much cleaner..  and pistons removed... crank looks good  lots of parts and tools on the way more pics on the way. Got a little more work done over the past few days and some parts. removed the main caps and girdle..  empty block  crank is out, i have a sneaking suspicion its bent between main 4 and 5... we'll see  and lastly picked this up on ebay.... OEM valve cover gaskets  Got another toy in today.... Starrett outside micrometer 2-3 inches .0001 inch resolution... to measure the crankshaft clearances properly to be able to hopefully rev 8000+ rpm. Still waiting on my angle torque gauge, and inside bore gauge to be able to send parts to the machine shop...  I was able to get some preliminary measurements on the crank to compare to the oem grades stamped to see the wear after 165000 miles of poor oil changes and owner negligence. Needless to say i was impressed on how little wear the motor had. Main bearings Journal 1 Grade 3 2.5173"-2.5176" My Measurement 2.5177" Journal 2 Grade 2 2.5176"-2.5178 My Measurement 2.5177" Journal 3 Grade 3 2.5173"-2.5176" My Measurment 2.5176" Journal 4 Grade 2 2.5176"-2.5178 My Measurment 2.5175" Journal 5 Grade 3 2.5173"-2.5176" My measurement 2.5177" As you can see little to no where on the mains. All with in spec The rods where a little different as those bearings where a little more beat up. Connecting rod journals Pin 1 Grade 1 2.0457"-2.04560 My measurements rod 1 2.0458" rod 2 2.0459" Pin 2 Grade 2 2.0455"-2.0457" My measurements rod 3 2.0457" rod 4 2.0458" Pin 3 Grade 1 2.0457"-2.04560 My measurements rod 5 2.0459" rod 6 2.0461" Pin 4 Grade 1 2.0457"-2.04560 My measurements rod 7 2.0460" rod 8 2.0460" As you can see still with in spec but slightly looser were talking .0002-.0003 inches here as expected This crank should just need some good micro polishing, and straightness check and be good to go. Got some more parts and tools in Clevite 77 bearings, .25 under, and fel-pro exhaust manifold gaskets..  Plus some tools.. Craftsman micro tq wrench 10-75 ft lbs, and fowler bore gauge 1.4-6 inches measures down to .00005 inches. Pretty good stuff.  Did some preliminary measuring on two rods just now... torqued them down to spec, and measured. Factory measurements are 2.1654"-2.1659" I got 2.1668 on one 2.1666 on the other. I verified the measurements with a second tool, the rods definitely need to be resized. This is why it is so important to have good measuring tools, if i where just slap them together with standard bearings and the crank measurement Id be at 2.1668 on the rod and 2.0460 on the crank. That leaves .1208, from the you subtract the thickness of the bearing times two (because there are two bearing halves) Lets go with a set of standards (which are the same size as grade 2 factories) .0594 thick X2 - .1188 total bearing thickness. Now we subtract the difference from the rod and crank (.1208) from total bearing thickness .1188 and get a oil clearance of .0020. This would probably be perfect and work good, But I'm gonna have the crank polished so its gonna be slightly smaller and i may have to resize the rods to adjust. Id like to run rod clearances in the mid 20s with mains around the low to mid 20s. Set up the bottom end on the block with out the crank so i could measure the mains for clearance purposes. Pic of the main on the block.. Notice the oil groove where the oil feeds the bearing from. People with sr20dets have to pay mazworx to cnc this for more oiling. We get it stock.  Main caps in place  girdle in place with bolts   Here is an absolutely critical tool required for tightening the main bolts, an angle torque gauge.  Just for giggles here is a pic of the mains that came out of a good running motor, it would have lasted to long with abuse. The rods where slightly worse.  Now i have to take apart the pistons and rods to press in the new rod bolts, resize the rods and balance them. So cleaning was required.  Super high tech piston dryer....  NIce and clean.  Heres todays lunch....

__________________

ANTI-STRETCH NAZI Vortech Supercharged Vh45de S14 V8nissans.com |

|

|

|

| Sponsored Links |

| Bookmarks |

|

|